Understanding the full expense of an information break is the initial phase in raising authoritative mindfulness.

The aftereffect of such a break can be catastrophic for an association with money and notoriety. Lamentably, information breaks are ordinary in the current world, even as network safety principles and techniques change and improve. If your association handles client data, forestalling information breaks utilizing best practices and a satisfactory NIST structure. Get familiar with the 4 prescribed procedures to prevent a data breach and help your association get ready. IF PRESSURE DROPS IN LESS THAT 31 SECONDS AT GREATER THAN 48% FLOW, THEN RUN BOTH COMPRESSORS IN THE NEXT CYCLE.It's not 'if' an information break happens, yet 'when'. Then timer T4:3 adds and measures this additional control function: If it is longer that 63 seconds, then start the 2nd unit.

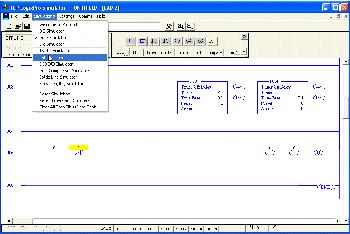

If you want to add even better control, use Subroutine 3 to control the LED display, and Subroutine 4 for "when 1 is not enough", with 2 additional timers, T4:2 that measures how long it takes a single compressor to fill the tank. See the attached picture for more details. You do this by carefully setting the Setpoint and Span of each pressure switch as follows: You have to use the PE1 pressure switch to start the 1st-run compressor (whether it be Compressor #1 or #2 as determined by the alternator bit B3/0), and then use PE2 to start the 2nd-run compressor if the 1st cannot keep up (pressure continues to drop even if one is running). Please help me out i got this so far i can get the two dual compressors to alternate but i cant get the one dual compressor to go full then drain then both start up.might be made. You should now have a good idea of where improvements BeforeĬontinuing to the next part, run your system with the flow rate adjusted to 78%, 80%, and thenĨ2%, and carefully note the result. Logic, with just a bit more effort you should still be able to even improve upon this. While this current solution likely performs as well as most systems employing relay Your program should now be able to handle both light and heavy demands for air quiteĮffectively. At 100% loading, both compressors should engage once it isĭetected that the pressure is continuing to drop. When at 50% loading, the compressors shouldĪlternate with each taking a turn. Operation at both 50% and 100% rates of flow. Once you have created your program, download it to the PLC and thoroughly test out its Please ensure that your system does actually operate in this This action will reduce the time it takes to bring the plant air system up to pressure, and Is first started and the tank pressure is initially being brought to within range of the pressure It is likely that your modifications will also result in both compressors being run when the system

0 kommentar(er)

0 kommentar(er)